Description

Area of Application

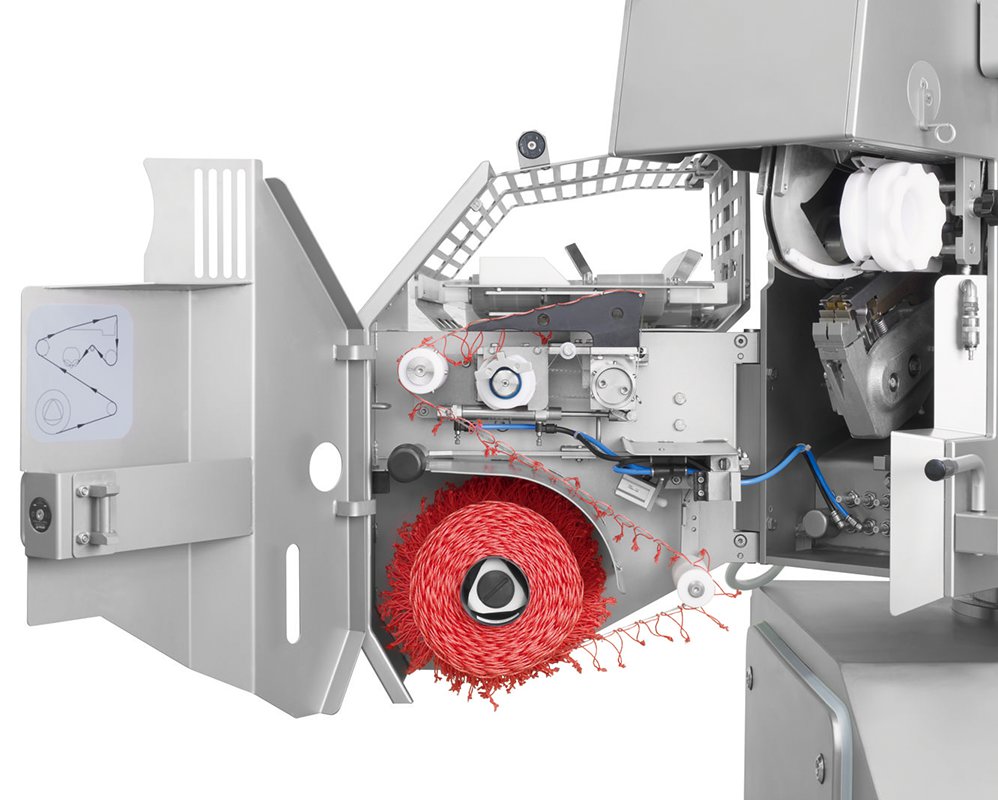

The TT automatic double clippers are the result of many years of experience and systematic product development. All familiar plastic, fibrous and collagen casings from caliber 35–140 mm (TT1815) and 20–80 mm (TT1512), can be cleanly and efficiently closed. Fast conversion to a different clip pitch (from 12 to 15 mm or from 15 to 18 mm) enables individual use and increases flexibility of the caliber range.

The TT automatic double clippers can be connected to all conventional filling machines. They seal the portions precisely to produce individual, string and ring sausages without sausage meat residue in the casing ends. This modern closure technology is also used for many applications outside of the food industry, e.g. for packaging semi-finished confectionery products, cheese, soups or non-food products.

Technology

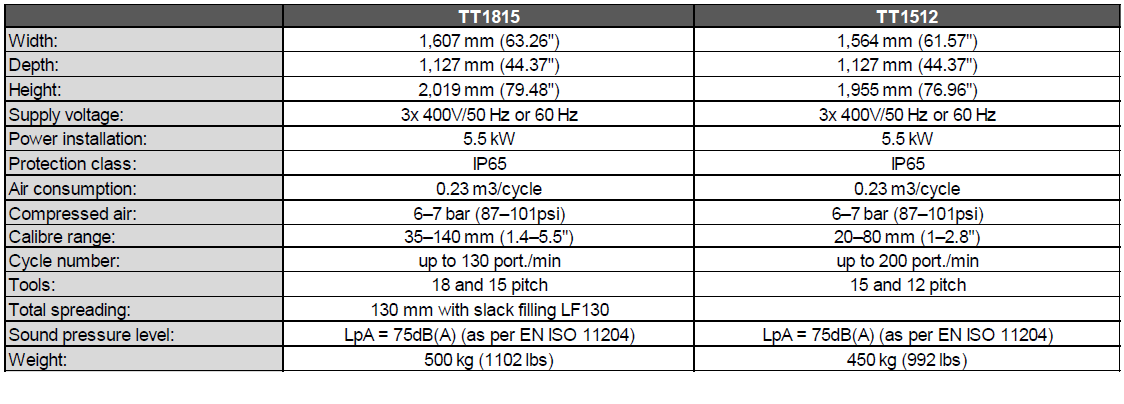

The electronic clip closure force monitor “NewCon” (Newton Control) prevents machine damage in the case of incorrect operation. If the set threshold value of the closing force is reached, the safety system is triggered and it stops the machine. The “NewCon” is a safety system which increases production reliability many times over. The clip closure height can be set consistently. The effective clip closing force is shown on the display.

The whole machine is completely stainless. All drive levers are made of stainless cast steel. Voiding is carried out via a cam disk. The cam roller is controlled both when opening and closing. The clip closure lever is moved via rim cams. These design solutions provide the TT automatic double clippers with a long service life and minimum wear.

For maintenance work, the clip cam can be manually controlled via the touch screen. The parameters for knife and tool changes as well as the cleaning position can also be called via the touch screen.

Control

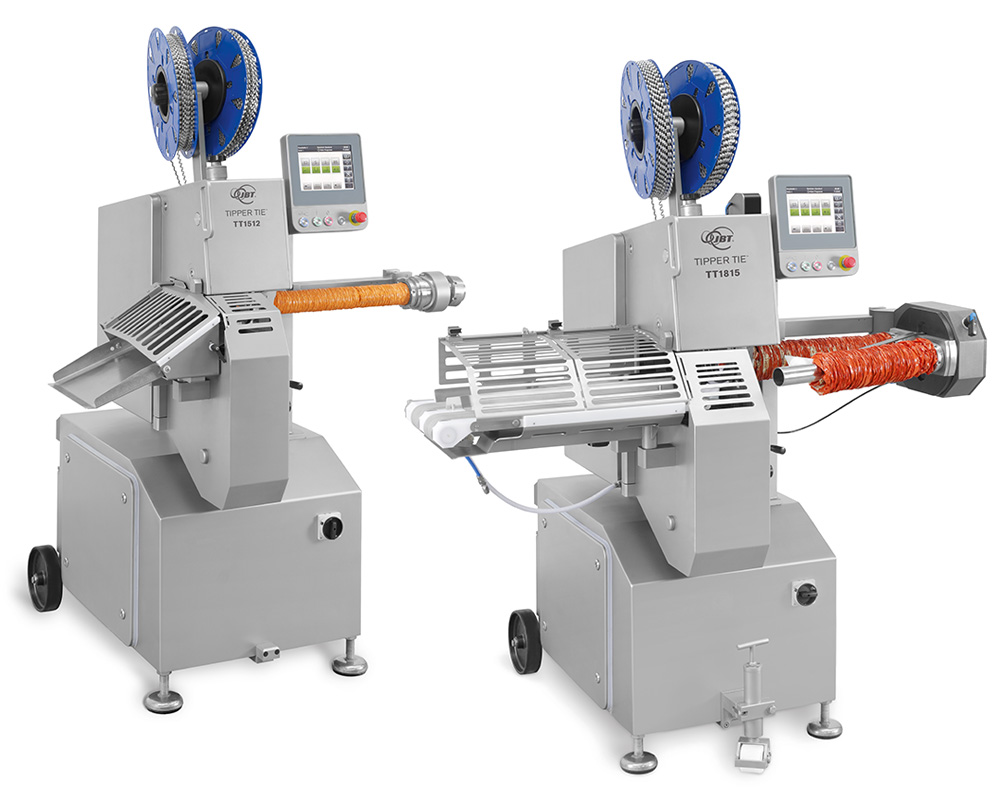

The TT double clippers are equipped with a maintenance-free servo drive and a PLC control. The machine is operated via a touch screen. This modern operating system with graphical visualization and alphanumeric plaintext display in many languages leaves nothing to be desired in terms of convenience, hygiene and efficiency.

Hygienic Design

The TT automatic double clippers offer a maximum of maintenance and service-friendliness. Smooth, stainless surfaces without bolt heads or corners where dirt can accumulate and horizontal surfaces with a 3° incline are design elements which allow fast, hygienic cleaning. The valves, drive and control are hermetically sealed against water and dirt by covers.

Equipment Versions

- String loop feeder BSZ 105-2

- Overspreading up to 130 mm (TT1815)

- Print mark control for centred trademark

- Clip and loop end detection

- Labeling system Tag print 60

- Single clip setting

- String dispenser for ring shaped products

- Mechanical and visual length portioning

- Swivel head, V-turret head or parallel turret head

- Belt outlet, chute in various designs

- Clip coding

- Pneumatic casing brake for sensitive casings

- Casing end detection

- Nose-wheel for easy manoeuvring

Advantages

- Ergonomic, compact design for high operating convenience.

- Manual clip cam adjustment via touch screen.

- Knife-, tool change and cleaning position selectable via touch screen.

- Reproducible clip pressure setting, adjustable from the outside.

- Electronic clip closure force monitoring “NewCon”

- Fast conversion to a different pitch with Click-Clip feed.

- Spring-powered gatherers guarantee a long service life.

- Air-free slack filling of shaped products with overspreading;total spreading 130 mm (TT1815).

- Hygienic cleaning thanks to smooth surfaces.

- 20 speeds plus continuous run for maximum productivity.

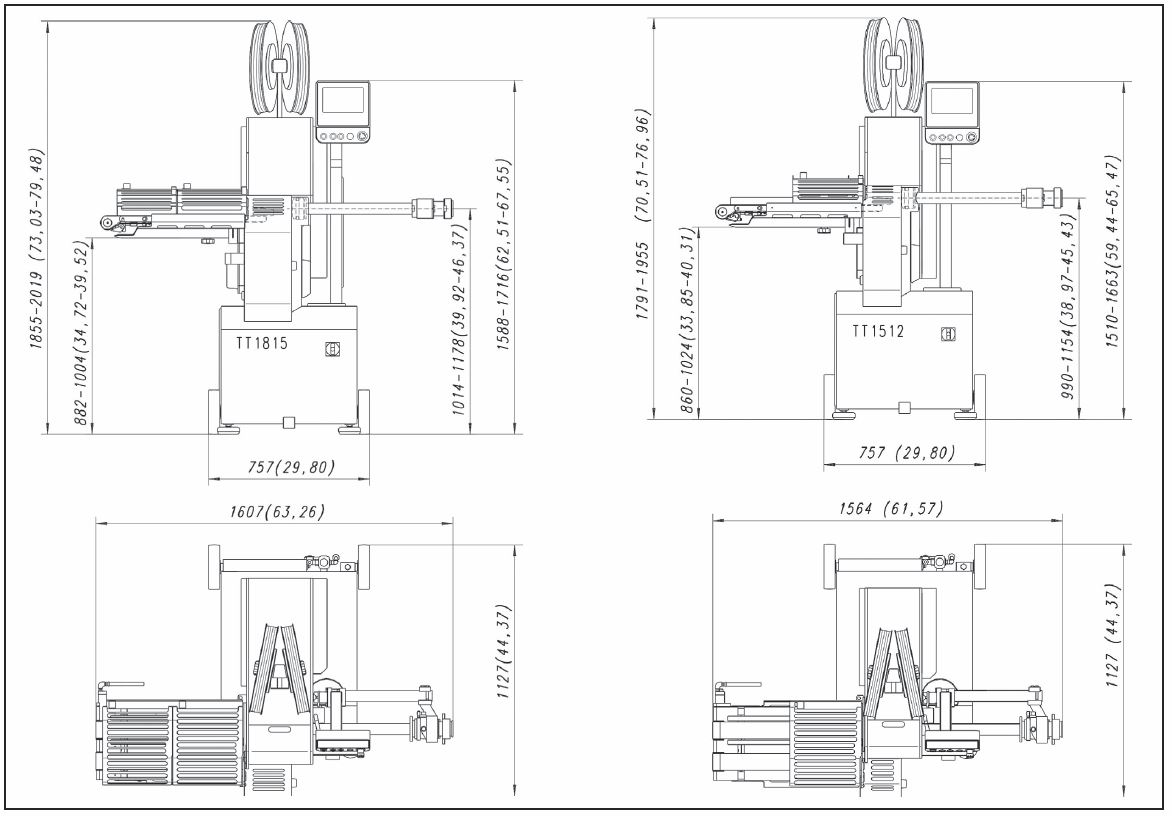

Technical Specifications