Description

Area of Application

The KDCMA is a fully automatic modular clipper. The complete range of basic and accessory components of these clipping machines made completely out of stainless steel is interchangeable. Every model can therefore be easily optimized for the required application. Natural, artificial and fiber casings in a caliber range of 25–120 mm are processed as raw, cooked or scalded sausages to make portions, rings, strings and slicing sausages, which are discharged either into a collecting pan or onto various roller conveyors. The movable, adjustable casing brake prevents overloading the casing and ensures exact filling of the portions. Operation via a modern touch screen control leaves nothing to be desired in terms of convenience and efficiency. If very simple operation is required, the trade setting (touch screen display with few controls) is set accordingly. For maximum accessibility when operating and cleaning the machines, they can be swivelled and have covers which can be opened wide. Thanks to the 10 degree slope, it is easy to see the working area. Stainless steel components with sloping surfaces and a new design with freely suspended lock plates meet maximum hygiene requirements.

Technology

Thanks to the use of single-action cylinders in the clip closure area, the machine is faster and has significantly lower air consumption. This saves money! Four displacer plates – for clean sausage tails, for processing various casings in a large caliber range. Simple, robust technology.

Control

Touch screen, 50 storable, readily accessible programs. The KDCMA is operated via a touch screen. This modern operating system with internationally recognized icons leaves nothing to be desired in terms of convenience, hygiene and efficiency. The user interface comprises the functions stop counter, portions per minute, system setting menu, machine switch menu, fault report, product setting menu fault position, loop test, label test, display of stuffer start.

Easy Service

The KDCMA clipping machine offers maximum maintenance and service-friendliness. The valves are installed on a service-friendly, “easy to change” pull-out bar. Quick and easy replacement of defective valves means short down-times and therefore increased efficiency. Open design in filler and closing area makes access to the work area an outstanding feature. Thanks to the well thought out design, service work can be carried out quickly and easily, which guarantees long work cycles and low repair costs. All valves are identical on the KDCMA. This means low stock level requirements. The functions of the valves can be checked via the control (step mode).

Design

The open design of the KDCMA is very service-friendly, as all necessary service areas are easily accessible. The consistent design is adapted to ensure high product quality, productivity and hygiene. Its robust design guarantees maximum stability and a long service life.

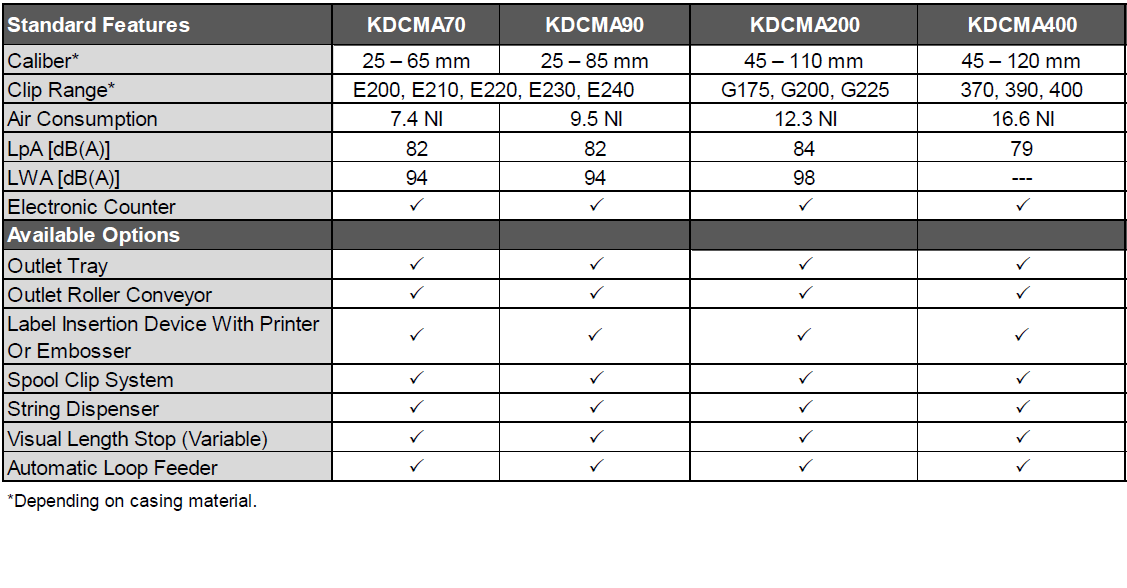

Options & Accessories

- Output tray for ring-shaped products.

- Outlet roller conveyor for chub-shaped products.

- Label feeder with printer for labelling the product.

- Spool clip system – to reduce reloading times for clips.

- String dispenser – for producing ring-shaped products.

- Visual length stop (variable) – to reduce cut-off residue when slicing.

- Automatic loop feeder – products can be suspended for the process or for presentation.

- Electronic counter – daily reproducible settings are possible.

Advantages

- Modular construction for adaptation to customer requirements.

- Hygienic design: inclined and smooth surfaces, easy cleaning thanks to good accessibility.

- Ergonomic inclination of the machine for improved handling and view of the production area.

- Comprehensive range of accessories.

- Single-action cylinders with low air consumption.

- Robust design.